THIN SHELL CONCRETE STRUCTURE–

TYPES & FORMS

Special Forms for Concrete Shells

A thin shell concrete structure, is a structure composed of a relatively thin shell of concrete, usually with no interior columns or exterior buttresses. The shells are most commonly flat plates and domes, but may also take the form of ellipsoids or cylindrical sections, or some combination thereof.

Types and Forms of Shell Structure

- Folded Plates

- Barrel Vaults

- Short Shells

- Domes of Revolution

- Folded Plate Domes

- Intersection Shells

- Warped Surfaces

- Combinations

- Shell Arches

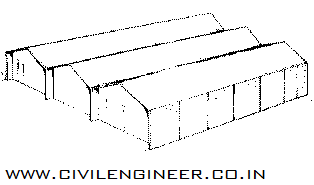

Folded Plates

The elements of a folded plate structure are similar to those of a barrel shell except that all elements are planar, and the moments in the slab elements are affected by the differential movement of the joints.

For the structure shown, the end supports and the side supports are both complete walls

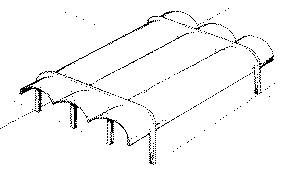

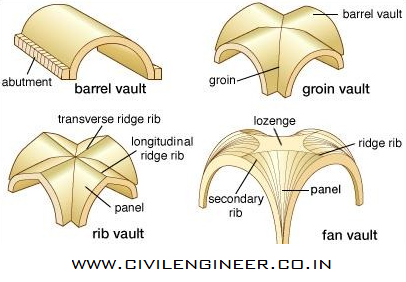

Barrel Shells

The elements of a barrel shell are:

(1) The cylinder,

(2) The frame or ties at the ends, including the columns, and

(3) The side elements, which may be a cylindrical element, a folded plate element, columns, or all combined.

For the shell shown in the sketch, the end frame is solid and the side element is a vertical beam.

A barrel shell carries load longitudinally as a beam and transversally as an arch. The arch, however, is supported by internal shears, and so may be calculated.

The elements of a folded plate structure are similar to those of a barrel shell except that all elements are planar, and the moments in the slab elements are affected by the differential movement of the joints.

For the structure shown, the end supports and the side supports are both complete walls

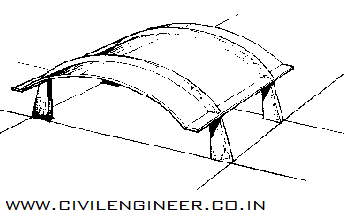

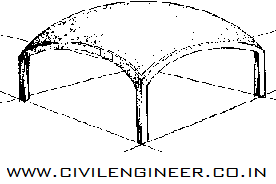

The elements of a short shell are the barrel, which is relatively short compared to radius, the element at the base of the cylinder to pick up the arch loads, and the arches or rigid frame to pick up the entire ensemble. In this case it is a rigid frame arch. The size of the arch could have been reduced by horizontal ties at the springings. There may be multiple spans.

The short shell carries loads in two ways:

(1) As an arch carrying load to the lower elements. and

(2) As as a curved beam to the arches.

The thickness of the shell can be quite thin due to these properties.

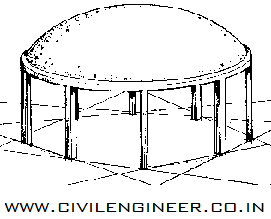

Domes

Domes are membrane structures, the internal stresses are tension and compression and are statically determinate if the proper edge conditions are fulfilled. In a dome of uniform thickness, under its own weight, the ring stresses are compression until the angle to the vertical is about 57 degrees. If the dome is less than a full hemisphere, a ring is required at the base of the dome to contain the forces.

Translation Shells

A translation shell is a dome set on four arches. The shape is different from a spherical dome and is generated by a vertical circle moving on another circle. All vertical slices have the same radius. It is easier to form than a spherical dome.

The stresses in a translation shell are much like a dome at the top, but at the level of the arches, tension forces are offset by compression in the arch. However there are high tension forces in the corner.

Advantages of Concrete Shells

Like the arch, the curved shapes often used for concrete shells are naturally strong structures, allowing wide areas to be spanned without the use of internal supports, giving an open, unobstructed interior. The use of concrete as a building material reduces both materials cost and a construction cost, as concrete is relatively inexpensive and easily cast into compound curves. The resulting structure may be immensely strong and safe; modern monolithic dome houses, for example, have resisted hurricanes and fires, and are widely considered to be strong enough to withstand even F5 tornadoes.

Disadvantages of Concrete Shells

Since concrete is porous material, concrete domes often have issues with sealing. If not treated, rainwater can seep through the roof and leak into the interior of the building. On the other hand, the seamless construction of concrete domes prevents air from escaping, and can lead to buildup of condensation on the inside of the shell. Shingling or sealants are common solutions to the problem of exterior moisture, and dehumidifiers or ventilation can address condensation.