Visual appearance of Plastic Cracks in Concrete

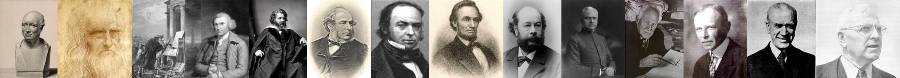

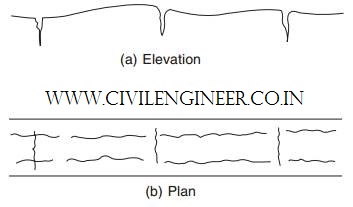

The most common restraint in slabs is from the reinforcement. The cracks occur on the top surface and usually follow the line of the uppermost bars, giving a series of parallel cracks; there may also be shorter cracks at right angles over the bars running in the opposite direction. Cracks are typically 1 mm wide and usually run from the surface to the bars (see Figures 1 and 2). The settlement may also result in visible undulations on the concrete surface, with the high points over the top reinforcing bars.

Plastic cracks in concrete

Fig. 1: General Plan view of cracks

Fig. 2: Section showing undulations

Fig. 2: Section showing undulations

In some cases where the bars in the top layer of reinforcement are close together, the whole surface layer of the concrete may be ‘suspended’ on the reinforcement while the concrete below settles. This can lead to a horizontal discontinuity beneath the bars, resulting in a loss of bond and with time delamination of concrete cover that protects the reinforcing steel against corrosion.

Unlike cracks in hardened concrete, due to overloading for instance, these cracks form at a very early age and pass through the cement paste and do not pass through aggregate particle pieces. The path is therefore more tortuous. This form of crack can be potentially serious as it passes longitudinal with the reinforcement and extends to the steel, negating the resistance to corrosion provided by the concrete.

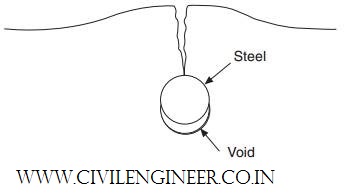

Fine cracks can occur in relatively narrow formed surfaces such as columns. The concrete may arch between the containing form faces. Settlement below the restrained concrete results in a crack being formed, generally coinciding with the links (see Figure 2.5). It is sometimes possible for plastic settlement cracks to form on a vertical face where reinforcement has restricted the free flow of concrete within the formwork. In such cases it is possible that the cracks are formed between the lines of the reinforcement.

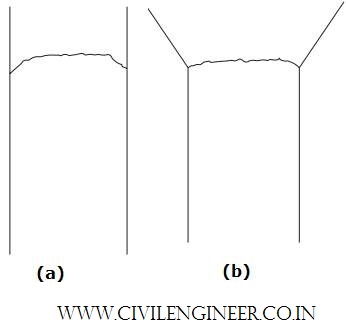

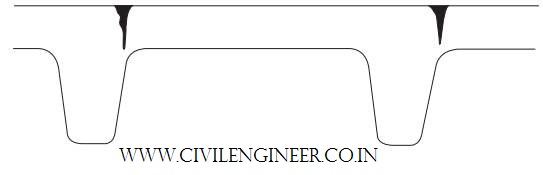

The concrete can also be supported by the formwork face. This causes restraint to the concrete between connected members and is especially evident where changes in section cause differential settlement, the concrete in the deeper section settling more than the shallower section resulting in a crack. This is noticeable in the transition between a flared column head (mushroom) and the plain column, and in trough and waffle slabs where more settlement takes place in the web than the comparatively thin flange (see Figures 3 and 4). The cracks may pass through the flange and appear similar to shrinkage cracks.

Fig. 3: (a) Arching near the top of column, cracking coincides with links. (b) Cracks at change of section.

Fig. 3: (a) Arching near the top of column, cracking coincides with links. (b) Cracks at change of section.

Fig. 4: cracks at change of section in trough and waffle slabs.

Fig. 4: cracks at change of section in trough and waffle slabs.

It can also occur at other locations, such as under spacer blocks. Cracks at mushroom heads of columns are generally horizontal. They are also typically 1 mm wide and can cross the full section.

If the sub-base or other material against which the concrete is placed has a high absorbency (dry soil, permanent forms) the settlement can be exaggerated, again the cracking following the reinforcement layout.