CONCRETE DAMAGES, DEFECTS AND PREVENTION

Concrete structure damages, defects and its prevention

Concrete structures get damaged or defective during its lifetime. The causes for such damages or defects can be many such as poor quality control during construction, overloads on structure, natural calamities, environmental factors etc. But it is essential to restore the strength of concrete structures by assessing and repairing of damages and defects.

For the successful repair and protection of concrete structure, technical assistance is needed from the experts. These include professional assessment of the damage, the design for use of suitable method of repair and then using the recommended methods to repair the damage or defects of concrete structures with due supervision and execution.

For the assessment of concrete structures for damages, it is required to know under which different circumstances the concrete structures may get damaged. Following are the given circumstance:

Concrete structure damage and defects:

The concrete structures get damaged or deteriorate due to mechanical, physical or chemical attack.

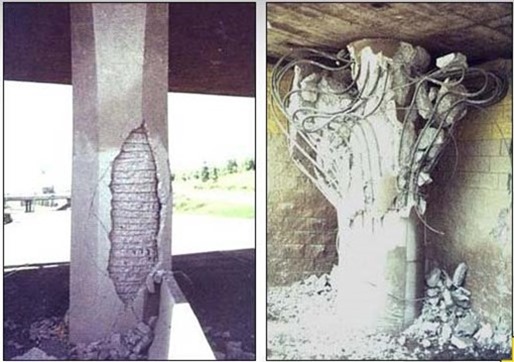

The Mechanical damages results in a concrete structure due to impact load on structure such as accidents, vibrations in the structure, due to which concrete get damaged and spall. Vibrations can be due to many reasons, such as moving heavy vehicles in surrounding, or explosion nearby, moving of heavy equipment inside structure or due to effects of wind loads and earthquake loads. With the vibrations in structure, concrete loose bonds with steel reinforcement and spalling of concrete may happen from structure.

Physical damage in concrete structure may occur due to abrasion, erosion of concrete, efflorescence or leaching, and even due to thermal effects. Erosion of concrete, leaching or efflorescence is the result of continuous contact of concrete structure with still or moving water. This results in damage of concrete structure resulting in corrosion of steel reinforcement which further decreases the strength and durability of concrete. The thermal effect is the result of continuous drying and wetting of concrete or where the temperature is high. In this case, the steel in concrete structure expands and contracts and bond is lost with concrete. This also results in crack in concrete members and thus spalling of concrete may happen.

The chemical attack on concrete structure is mostly based on environmental condition or surroundings where the concrete structure is constructed. The environmental condition such as concrete structure nearby coastal areas gets damaged earlier than other regions due to rapid corrosion of steel reinforcement. The concrete structures nearby any chemical factory also gets damaged due to chemical actions.

Other type of chemical damages can be due to bacterial attack, direct chemical exposure or alkali aggregate reactions. Alkali aggregate reaction happens due to presence of alkali’s in sand.

Concrete damage due to steel reinforcement corrosion :-

Reinforcement steel in concrete structures gets corroded due to chemical attack as mentioned above or due to poor construction practices during execution which results in less durable structure. To prevent the corrosion in steel reinforcement, it is essential to provide required cover as per the relevant codes based on environmental conditions. Strictly following codal provisions in design and construction of concrete structure for the given region prevents such kinds of damages and defects. The selection of suitable painting, use of epoxy coated steel reinforcements and types of cement also helps in preventing steel reinforcement corrosion.

Damage by Carbonation: The carbon dioxide ingress causes carbonation of the cement matrix.

Another damage is the results of metals of different electro potential that are connected to each other in the concrete and corrosion would occur. Such damage is commonly calling “Stray/Electrical current” damage.

The Contamination by corrosives like Chlorides is carried into the concrete in solution in water. At the steel surface, even in alkaline concrete, they attach and break down the passivating layer and then accelerate the steel corrosion process.

Nicely written and very informative article.